How a stretch wrapping machine supports bulk packaging

How a stretch wrapping machine supports bulk packaging

Blog Article

Discover the Advantages of Using a stretch wrapping machine for Reliable Packaging Solutions

Worldwide of packaging remedies, effectiveness is essential. Automation has brought forth significant improvements, such as the stretch wrapping machine. With its ability to cover items firmly and swiftly utilizing elastic plastic movie, it uses a high level of accuracy and speed. It's not almost covering items, yet additionally regarding reducing labor prices, minimizing waste, and maintaining visual charm. So, what makes these machines a game-changer in the product packaging industry?

Understanding the Performance of Stretch Covering Machines

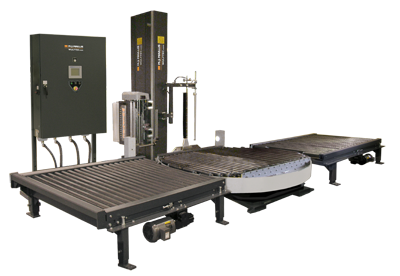

Pioneering the packaging market, stretch covering devices simplify the procedure of securely packaging products for transportation or storage space. These sophisticated devices employ a straightforward yet effective system, using an elastic plastic movie that is twisted around things, providing stability and protection. The products, commonly prepared on a pallet, are revolved as the movie is given, ensuring a tight and protected cover.

The movie's flexibility offers a double function: it securely binds the things with each other, lowering the threat of damages as a result of activity, and it supplies an obstacle versus dust, wetness, and other potential hazardous elements. Furthermore, the transparent nature of the stretch film allows for easy recognition of the packaged things.

The machines differ in their procedure setting, with some being semi-automatic, needing very little human intervention, and others being completely automated, with the ability of separately managing the entire covering procedure. No matter of their mode, stretch wrapping machines are a keystone of secure and effective packaging.

How Stretch Covering Machines Enhance Efficiency

Boosting performance degrees considerably, stretch wrapping equipments improve the packaging procedure with their automated abilities. These advanced makers allow firms to wrap a high volume of bundles rapidly and successfully, providing a consistent covering output that hand-operated methods merely can not match. This speed and uniformity translate straight into raised productivity, making it possible for services to meet requiring supply schedules and consumer expectations.

Additionally, stretch covering devices call for minimal human treatment. Once the device is established up and the wrapping criteria are configured, the maker can operate separately, maximizing employees to concentrate on various other vital jobs. This automation not only decreases labor prices but additionally eliminates human errors, ensuring the quality of covering continues to be consistent.

Additionally, using stretch covering devices commonly leads to less downtime. stretch wrapping machine. With their robust style and trusted operation, these devices are much less vulnerable to breakdowns and maintenance problems, making certain uninterrupted workflow and improved productivity

Reducing Product Waste With Stretch Covering Machines

While improving efficiency, stretch covering equipments additionally play a vital duty in lowering product waste. The precision of these equipments makes certain that each plan is covered with the specific quantity of product required, lessening excess waste. This accuracy not just leads find out this here to a visually pleasing and constant package, but also contributes significantly to ecological sustainability.

Fundamentally, the use of stretch wrapping makers in a product packaging line is not only an action in the direction of efficient efficiency, yet likewise a jump in the direction of environmentally friendly techniques by significantly minimizing product waste.

Cost Reduction: A Secret Advantage of Stretch Wrapping Machines

In addition to mitigating product waste, an additional significant advantage of stretch wrapping makers is their potential for cost reduction. These makers are reliable, requiring less hands-on labor for packaging products, therefore minimizing labor expenses.

Moreover, stretch covering equipments use less material to package goods safely as compared to standard covering techniques. This reliable use materials not only decreases waste but also decreases expenditure on product packaging materials.

The equipments additionally decrease damages to items throughout transportation. With tough and safe product packaging, the threat of item damage reductions, lowering the expenses connected with item returns and replacements.

Finally, the rate and effectiveness of stretch covering machines can boost production prices. Faster packaging times mean that services can package and ship even more products in less time, boosting total performance.

Carrying Out Stretch Wrapping Machines in Your Packaging Refine

Offered the excellent benefits of stretch wrapping equipments, including them into your packaging procedure can be a game-changing decision. The implementation procedure needs careful preparation and training to make sure ideal utilization. Initially, an evaluation of the current product packaging procedure is required to establish the excellent maker type and dimension. The option should straighten with the package dimensions, weight, and the volume of products to be wrapped daily.

Training personnel on maker operation is crucial. This includes comprehending the device's performances, fixing common concerns, and adhering to security standards. By doing so, companies can ensure a reliable, cost-efficient product packaging process, reaping the full advantages of see this page their investment click to read in stretch wrapping devices.

Conclusion

In verdict, stretch wrapping equipments offer effective, cost-effective product packaging services. These makers guarantee product security and security, while likewise supplying visually pleasing packages.

Once the equipment is established up and the wrapping parameters are set up, the device can operate separately, freeing up workers to focus on various other crucial jobs.While enhancing efficiency, stretch wrapping devices additionally play an essential role in minimizing product waste.Provided the remarkable advantages of stretch covering equipments, incorporating them into your packaging procedure can be a game-changing choice - stretch wrapping machine. By doing so, businesses can ensure an efficient, cost-effective packaging process, reaping the complete advantages of their financial investment in stretch covering makers

In verdict, stretch covering devices provide effective, affordable packaging solutions.

Report this page